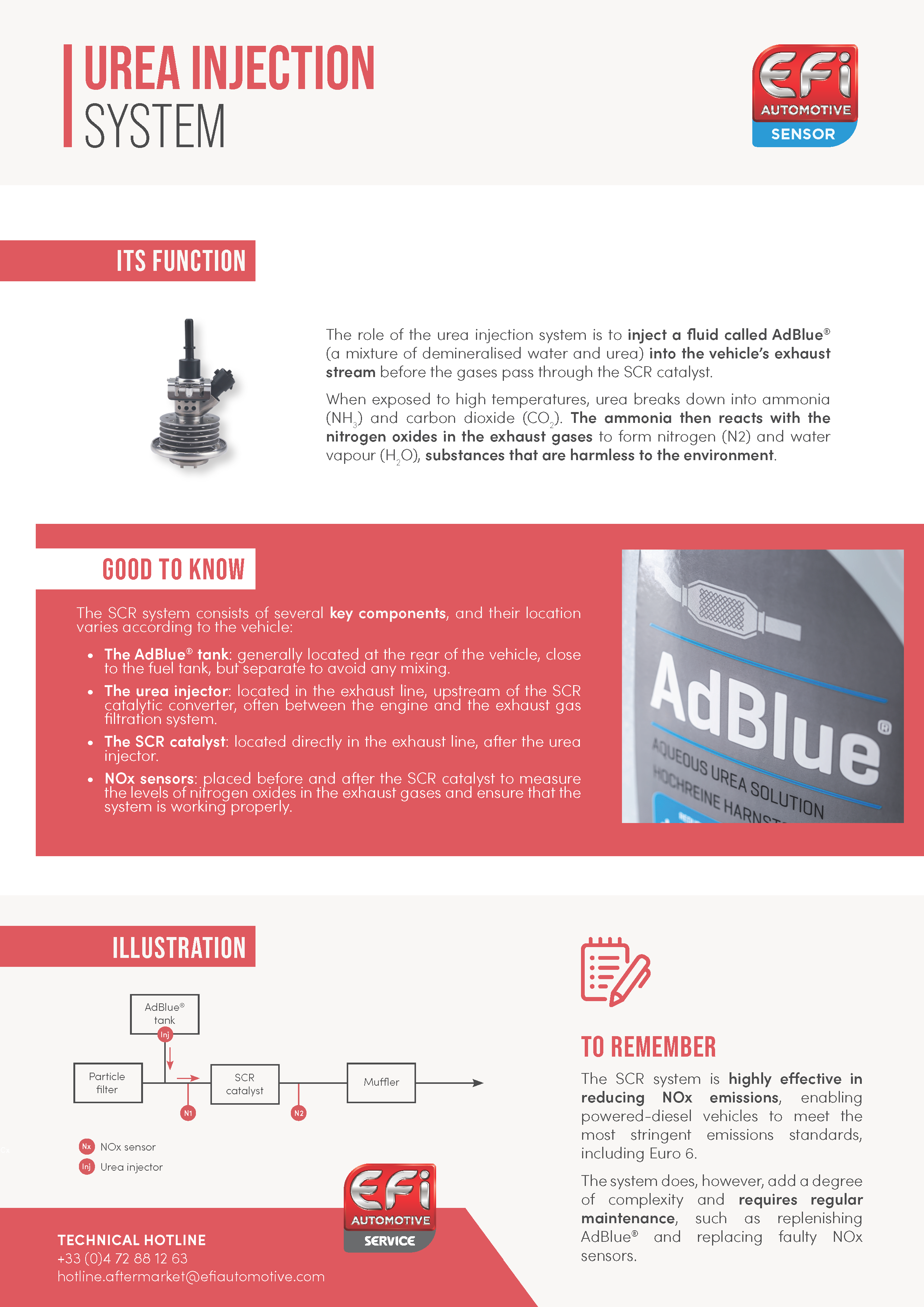

Most vehicles fitted with a urea injection system have specific warning indicator lights that will indicate if there is an issue linked to any failure. Sometimes, an engine check indicator light may also come on. It is very likely that engine power will be limited to avoid increasing pollutant emissions. This can result in a drop in performance, reduced acceleration, or irregular engine behavior. If the injection system is not working properly, it may overconsume the AdBlue® solution. Due to poor NOx management, your vehicle may emit more smoke or darker smoke. If the urea is not injected correctly or if the chemical reaction in the catalytic converter does not take place as expected, you may detect an unusual smell coming from the exhaust, which is linked to incorrectly processed gases. In some cases, to protect the engine and limit emissions, your vehicle may switch to downgrade mode. This considerably reduces the maximum speed and overall performance, making driving difficult until the issue is resolved. Malfunctioning of the SCR system leads to increased pollutant emissions, especially nitrogen oxides (NOx). This issue may be detected during a technical inspection or an emissions test, where the vehicle fails to meet pollution standards.