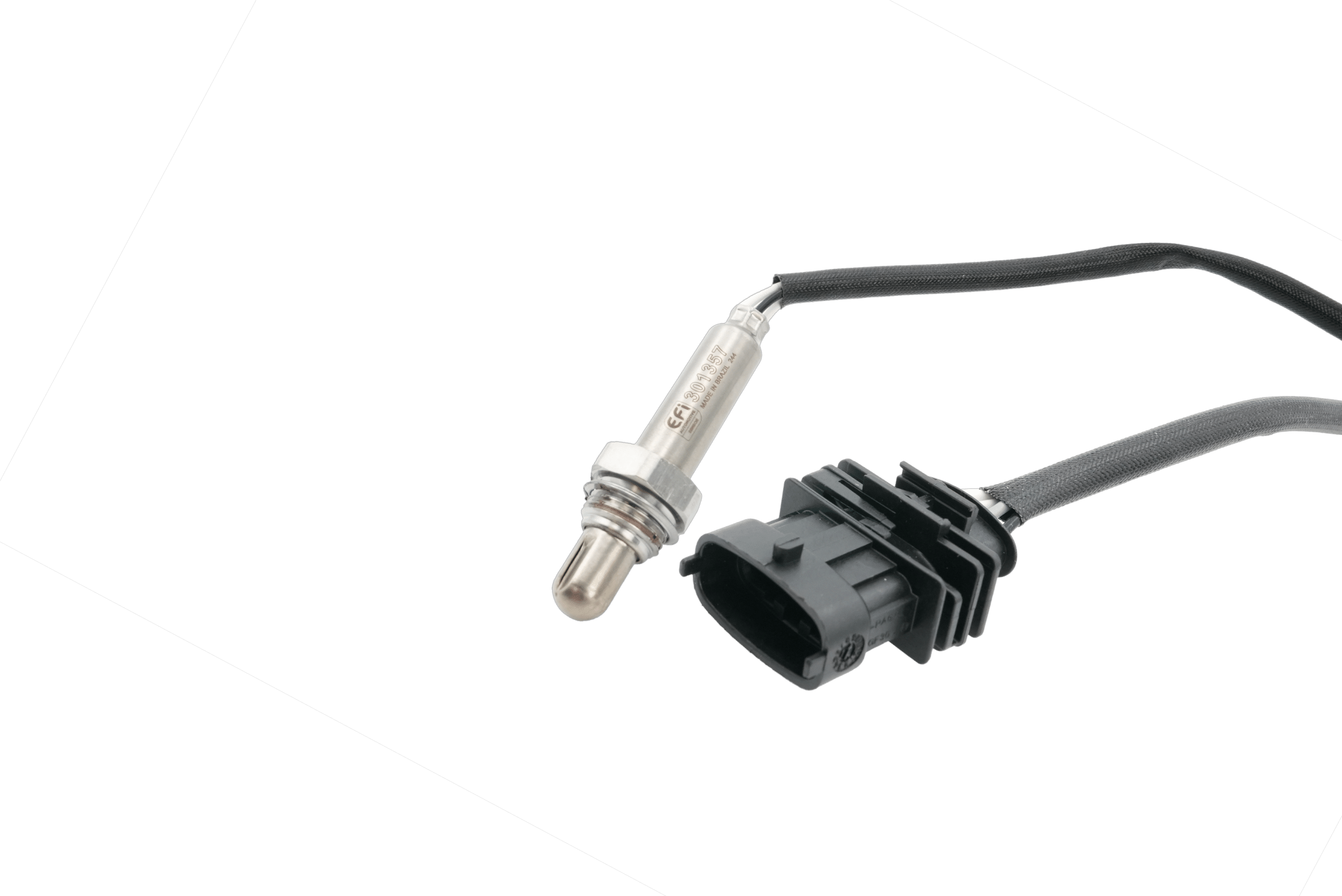

BROADBAND LAMBDA SENSORS

Unlike the zirconia and titanium dioxide oxygen sensors, which send a binary response to the ECM, broadband technology sends continuous information to the ECM, corresponding to the lambda value detected. It consists of two electrochemical cells which operate simultaneously. One of these cells (the measuring cell) measures whether the mixture is rich or lean, while the second (the pumping cell) reacts, conditioned by the first and the quantity of oxygen in the exhaust gases. The joint operation of the cells results in an electrical current which is positive for a lean mixture, negative for a rich mixture, and zero in the case of a perfect lambda. The current generated by these sensors is calibrated and must be converted into voltage so that the vehicle’s ECU can process the information.

This is why broadband technology is more accurate than the previous two, as it measures the exact composition of exhaust gases, making it suitable for both diesel and petrol vehicles.

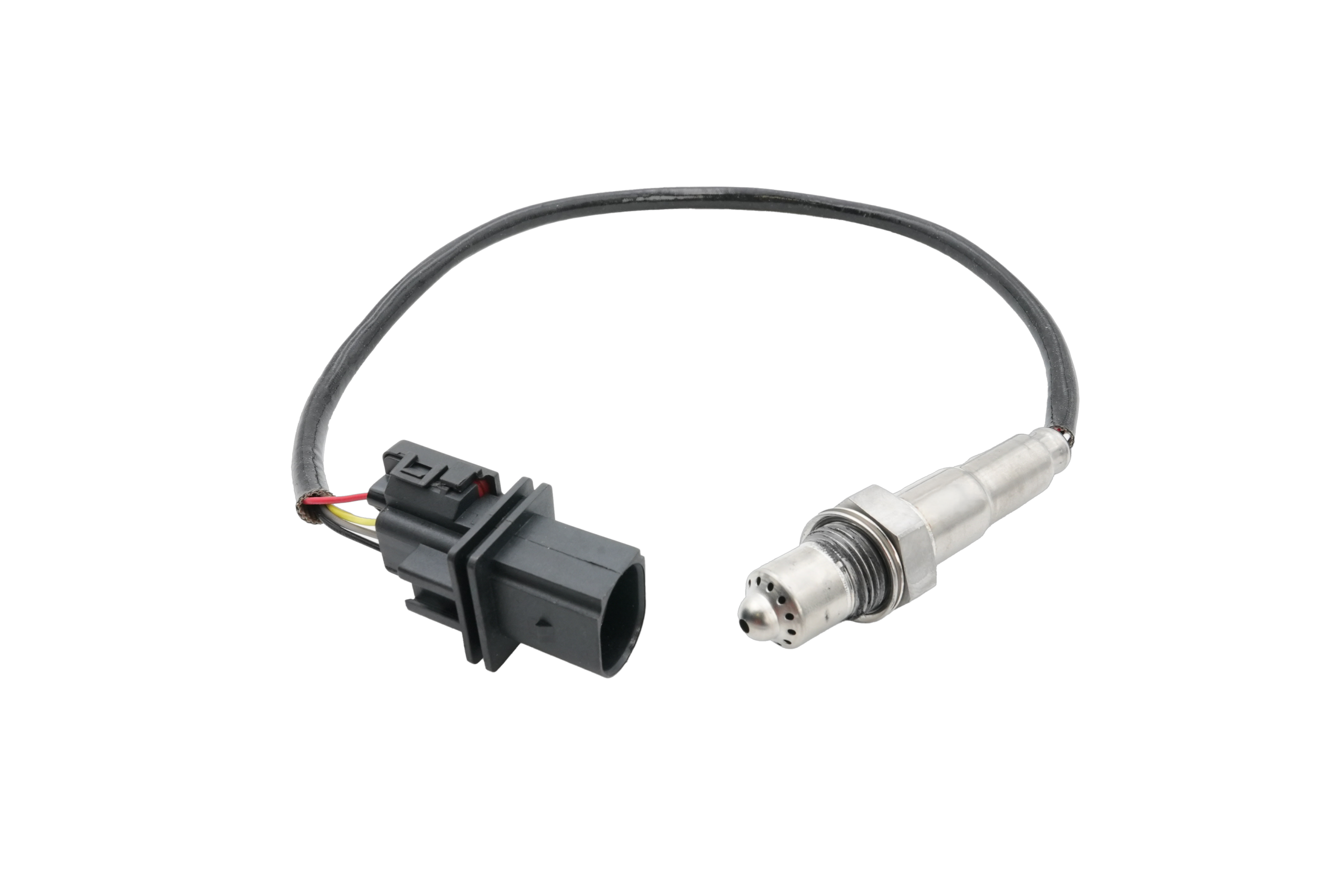

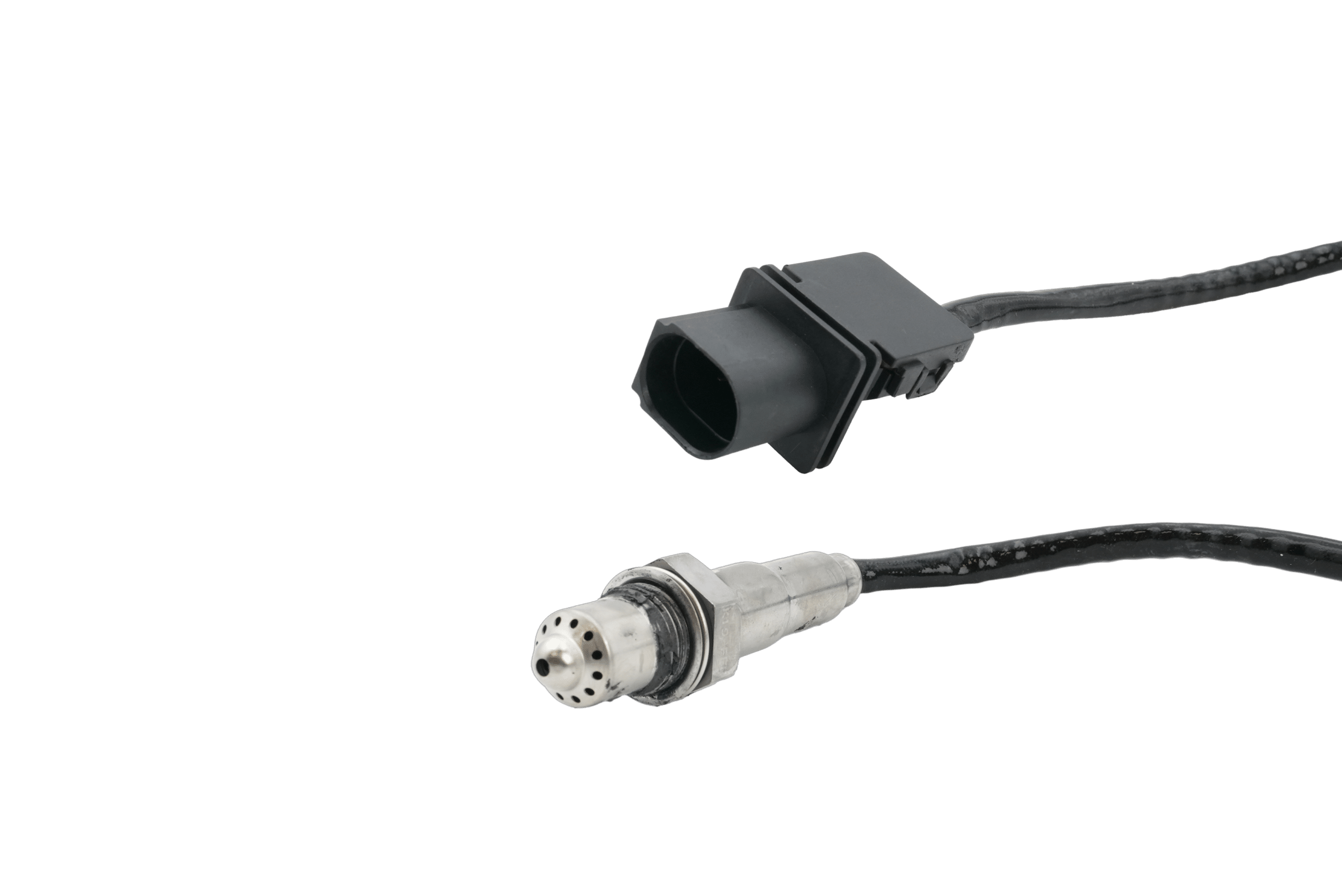

However, there are three generations of broadband sensors on the market. The first contains an external air reference channel like that in zirconia oxygen sensors. The second generation no longer needs this channel to operate. The absence of a channel means lower power consumption, shorter warm-up times, and greater signal stability. The third generation relates to the air-fuel ratio broadband sensor. Because this is specific, it will be described in the next section.

Note: depending on the vehicle applications, first- and second-generation broadband oxygen sensors may be required (and are still available on the market) but are in no way interchangeable.