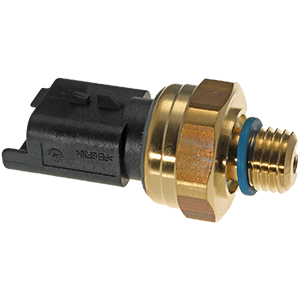

When an oil level sensor is faulty, the oil warning indicator light comes on randomly or remains on even when the oil level is correct. Or conversely, the sensor does not indicate that the oil level is too low, even if the engine is running low on oil. The oil indicator light may also intermittently turn on and off, with no link to any real fluctuation in the oil level. In addition to the oil warning, other errors may appear on the on-board computer, linked to the electronic management of the engine. Unusual and excessive oil consumption may appear regularly due to frequent or erroneous warnings from the sensor. In some vehicles, a faulty sensor may prevent the engine from starting up, or it may force the vehicle to switch to safety mode to avoid potential damage. A specific error message may appear on the on-board computer, indicating an issue with the oil level sensor or an issue reading this sensor.