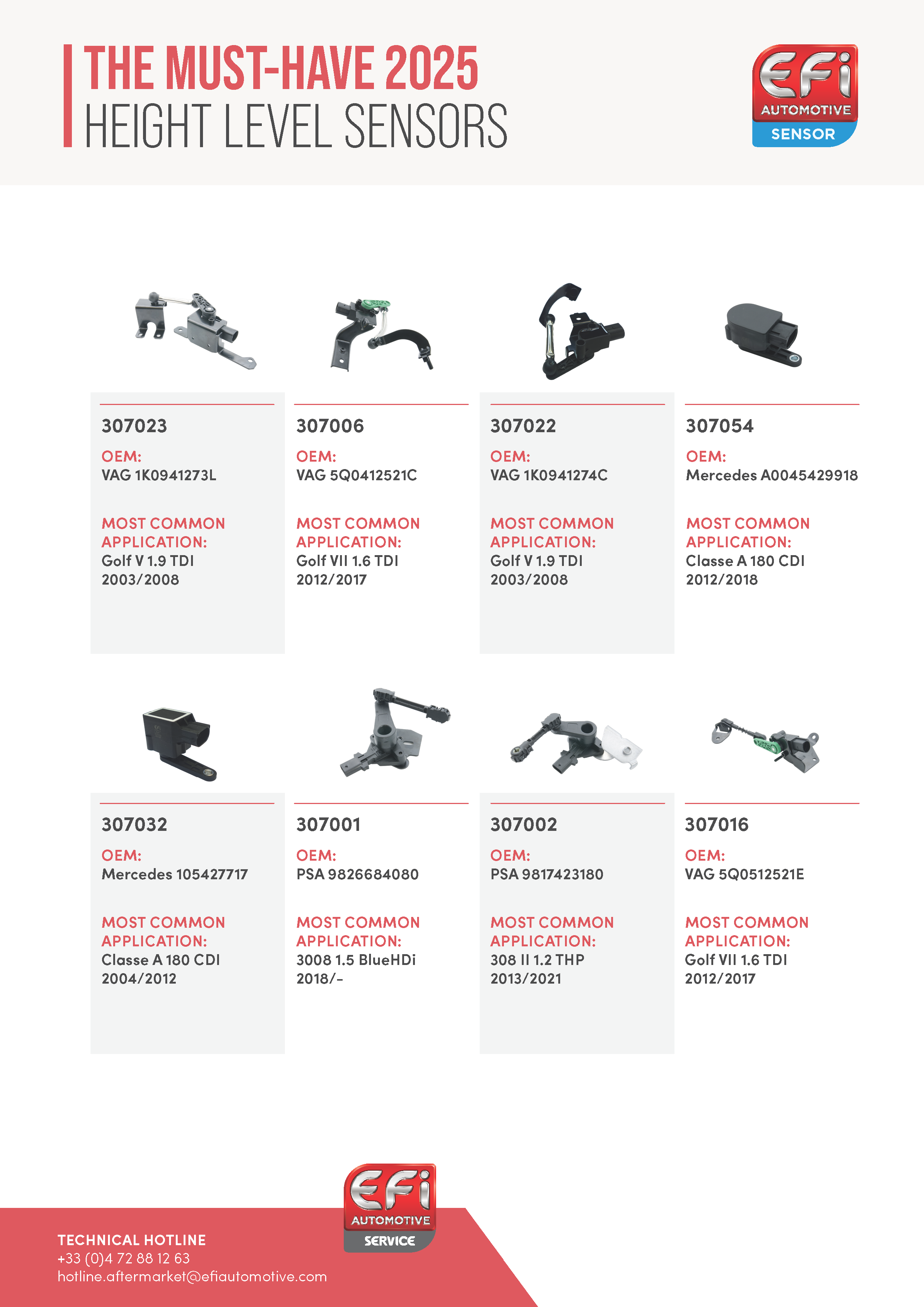

When the height level sensor is faulty, the suspension or stability warning indicator lights may light up on the dashboard. Error messages or specific warnings about the suspension or the body height may also appear. Issues with the vehicle’s suspension may be felt: The vehicle may appear to be lower or higher on one side or at the front or the rear. It may not adjust the suspension correctly, resulting in uncomfortable driving, and the air or adaptive suspension systems may not adjust the body height as intended. Vehicle handling and stability issues may also develop. As a result, the vehicle may become less stable, especially when cornering or at high speed. The vehicle may lean excessively or behave unpredictably when cornering. If the height level sensor is associated with the automatic headlight adjustment system, the headlights may be misaligned, creating a light beam that is too high or too low. The failure of the sensor can also have an impact on driving comfort, with the appearance of vibration or jolting. Faulty sensors can affect stability and traction control systems, reducing their effectiveness. Vehicles fitted with adjustable driving modes may not switch modes correctly, or may deliver sub-optimal performance.